In the rapidly evolving landscape of manufacturing, technological advancements have always played a pivotal role in driving efficiency, productivity, and innovation. Among the latest disruptors, Artificial Intelligence (AI) emerges as a game-changer, reshaping traditional manufacturing processes and unlocking a realm of possibilities. From predictive maintenance to quality control and supply chain optimization, AI is revolutionizing every aspect of manufacturing operations, propelling the industry towards unprecedented levels of excellence.

Together we will go through the different aspects of using AI solutions in production.

The place of AI in manufacturing processes

Predictive Maintenance

One of the most prominent applications of AI in manufacturing is predictive maintenance. By harnessing the power of machine learning algorithms and real-time data analytics, manufacturers can anticipate equipment failures before they occur. This proactive approach reduces maintenance costs, and extends the lifespan of machinery. What is the most important it might minimizes unplanned downtime - by identifying and addressing potential equipment failures before they occur, predictive maintenance minimizes unplanned downtime, thereby enhancing production continuity and overall equipment effectiveness.

AI algorithms analyze historical data, equipment performance metrics, and environmental factors to predict potential issues accurately, enabling timely interventions and optimized maintenance schedules.

Data-Driven Insights

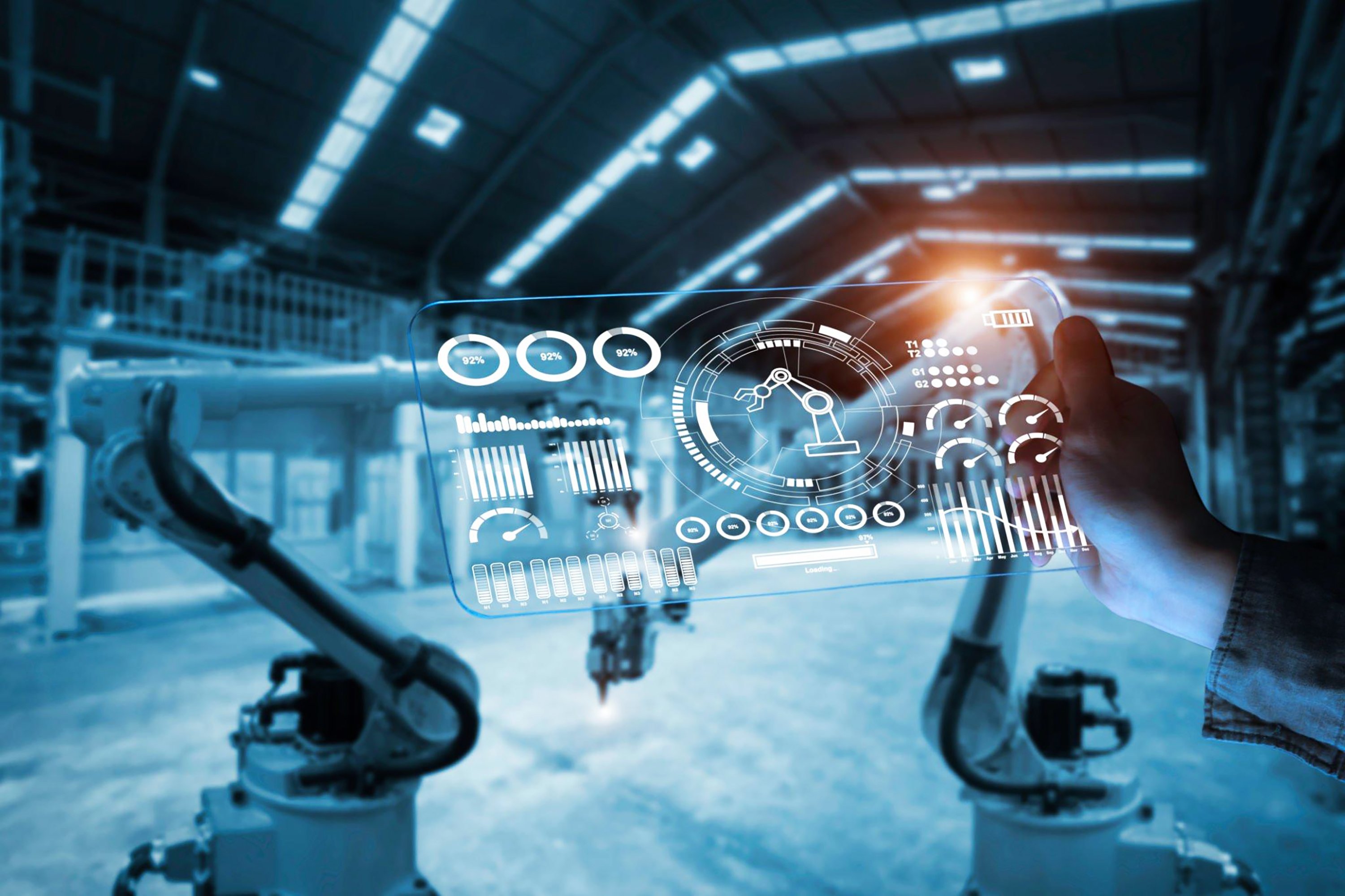

At the heart of predictive maintenance lies the utilization of vast amounts of data generated by industrial equipment, sensors, and IoT devices. AI algorithms ingest and analyze this data, identifying patterns, trends, and anomalies indicative of potential equipment failures. By examining parameters such as temperature, vibration, pressure, and electrical currents, predictive maintenance systems can discern early warning signs of impending malfunctions or degradation in machinery.

One of the primary objectives of predictive maintenance is to accurately predict when equipment failures are likely to occur. AI algorithms leverage historical maintenance records, equipment performance data, and contextual information to forecast potential failure modes and their likelihood within a specified timeframe.

By analyzing patterns of degradation and failure precursor signals, predictive maintenance systems empower manufacturers to schedule maintenance activities proactively, minimizing downtime and maximizing asset uptime.

In addition to predicting equipment failures, AI-powered predictive maintenance systems provide prescriptive recommendations for maintenance interventions. These recommendations are based on sophisticated algorithms that weigh factors such as the criticality of the asset, the severity of the impending failure, and the cost implications of various maintenance actions. By prioritizing maintenance tasks and optimizing resource allocation, manufacturers can ensure that maintenance efforts are targeted effectively, minimizing disruption to production processes while maximizing the lifespan of assets.

Process Automation and Robotics

AI-powered robotics and automation technologies are revolutionizing production processes, enabling manufacturers to achieve unprecedented levels of efficiency, flexibility, and scalability. Collaborative robots, or cobots, work alongside human operators, enhancing productivity and safety on the factory floor. By automating repetitive tasks and streamlining workflows, AI-driven robotics empower manufacturers to optimize resource utilization, improve throughput, and adapt quickly to changing production demands.

Quality Control and Defect Detection

Ensuring product quality is paramount in manufacturing, and AI-driven systems play a crucial role in enhancing quality control processes. Machine learning algorithms can analyze vast amounts of visual data from cameras and sensors to detect defects with unparalleled accuracy and speed. From identifying surface imperfections to detecting dimensional variations, AI-powered quality control systems enable manufacturers to maintain stringent quality standards, reduce rework, and mitigate the risk of defective products reaching the market.

Supply Chain Optimization

In today's globalized manufacturing landscape, supply chain optimization is imperative for maintaining competitiveness and meeting customer demand efficiently. AI algorithms optimize supply chain processes by analyzing complex data sets, including demand forecasts, inventory levels, production capacity, and logistics constraints. By leveraging AI-driven predictive analytics, manufacturers can make informed decisions regarding inventory management, production planning, and logistics optimization, thereby minimizing costs, reducing lead times, and enhancing overall supply chain agility.

Energy Management and Sustainability

Sustainability has emerged as a key priority for modern manufacturers, driven by environmental concerns and regulatory requirements. AI plays a vital role in optimizing energy consumption and reducing carbon footprint across manufacturing facilities. By analyzing energy usage patterns, AI algorithms identify opportunities for efficiency improvements and recommend actionable insights to minimize energy waste. From optimizing equipment schedules to implementing smart energy management systems, AI-driven solutions enable manufacturers to achieve their sustainability goals while reducing operational costs.

The integration of AI into manufacturing operations heralds a new era of innovation, efficiency, and competitiveness. By leveraging AI-driven technologies across various facets of production, manufacturers can unlock new opportunities for growth, improve operational performance, and deliver superior products to customers worldwide. As AI continues to evolve and mature, its transformative impact on manufacturing will only deepen, driving continuous improvement and shaping the future of the industry.

%20(1680%20x%20950%20px).png?width=468&height=263&name=Lukas%20Broisch%20(300%20x%20175%20px)%20(1680%20x%20950%20px).png)